Case studies

| Project description | Proposed solutions | Achieved results |

|---|---|---|

| Customer type Industrial confectioner Aim of mission Dioxide Titanium substitution Products Panned chewing candy (Hard panning) Constraints Client would like to eliminate titanium dioxide from his labels without using new ingredients. | Trade lever Develop two ranges of colours: 1/ Dark colours range 2/ “rustic style” natural colour range Technical lever Improve performance of the air treatment installation in terms of air flow and absolute humidity. Operational lever 1/ Realize precoating of the centres in order to have smooth centres without holes before the panning. 2/ Increase the brix of syrup during engrossing in order to obtain big crystals which are more opaque. 3/ Increase proportion of Gum Arabic in syrup (already mentioned in the ingredient list) Managerial lever 1/ Train the operators to the precoating techniques and improve competences in hard panning 2/ Change work habits, in order to have the same objectives as marketing. | Sales analysis 1/ Very good results on dark colours Defect rate has not increased 2/ Limited result on pastel colours. Not only, the colours are not very bright but colours are not uniform, this is due to a lack of whiteness in underlayers. Technical analysis Investment on the air treatment installation enables a substantial productivity increase. Managerial analysis Very good involvement of staff who appreciate the new air treatment installation. Improvement of competence level and understanding of the staff and the manager. The staff has proposed to do the engrossing of the pastel colour in two steps in order to increase the whiteness of the layer (this proposition is not retained yet because of storage problems). |

Decrease waste rate

| Project description | Proposed solutions | Achieved results |

|---|---|---|

| Customer type Industrial confectioner Aim of mission Decrease waste rate Products Chocolate panned Constraints No possibility of investment | Managerial Lever 1/ Train the operators to chocolate panning and chocolate polishing : - Using a “risk table” to fill-in as support each parameter will be explained and understood during the two operations. - Using a “correcting table” to fill-in to develop the right reflexes. - Sharing professional panners experience to find a common operating mode 2/ Agree on a sustainable operational mode implemented by all operators. Operational lever Add ageing time after chocolate panning and before varnishing to obtain a better crystallized chocolate and so harder shell. | Sales analysis Lower waste rate after one year. Operational Analysis Although more handling is imposed by this action, the operators agree to unload the pans between panning and glazing as quality improvement has been revealed. Managerial analysis Difficult communication amongst the operators « juniors and seniors ». The trainer managed to establish trust within the team thanks to his thorough field and pedagogical experience. The operating modes were tested hands on. The seniors were glorified during the training and the juniors were able to defend their ideas. |

Increase quality of glazing and improve productivity

| Project description | Proposed solutions | Achieved results |

|---|---|---|

| Customer type Artisan chocolatier 50 employees Aim of mission Increase quality of glazing and improve productivity Products Dried fruits and almonds brittle chocolate panned Constraints Spending limit to K€50 | Technical lever Define needs of pans and air treatment Define layout plan of machines Project management Operational lever 1/ Simplify the actual operational mode of the chocolate panning using performance of the air treatment installation 2/ Define rigorous procedure for chocolate glazing Managerial Lever 1/ Explain to the operators the rule of each parameter of the glazing operation. 2/ Encourage operators to take measures in order to better anticipate climatic variations. | Sales analysis Time required / batch has decreased from 3 hours to 1h15 (time for loading, pan coating, smoothening and unloading) The waste rate has decreased (invalid batches) Quality product is more uniform. Technical analysis . Pan purchase of second-hand copper pans already equipped with frequency converter. . Installation of air treatment realized by a subcontractor according to our specifications . Installation of a new ageing room according to our specifications . Purchase of efficient measuring tools. Managerial analysis . Better understanding of the reasons for defects on polished chocolate sweets. |

Start chocolate panning activity

| Project description | Proposed solutions | Achieved results |

|---|---|---|

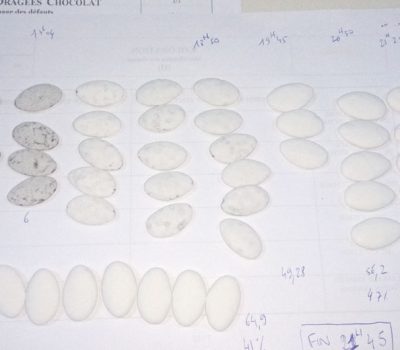

| Customer type Artisan chocolatier 2 employees Aim of mission Start chocolate panning activity Products Chocolate panned dried fruits Constraints Limited budget | Trade lever Define a simple range: hazelnuts and almonds coated with dark chocolate and milk chocolate. Finishing : glazed with a strong shiny Technical lever Acquire equipment : pan + air treatment mobile installation Managerial Lever Do the training “The manufacturing of chocolate panned candies” in Montauban after Easter’s season (1.656 €/3 days - French language) | Sales analysis Purchase 60 kg second-hand pan: € 4900 Purchase Air treatment mobile installation: € 6000 Purchase 64 perforated plastic containers: € 820 Sale price of candies : € 35/kg Managerial analysis The artisan quickly acquired the necessary skills for simple panning. He’s improving by producing every day and has increased his range to white chocolate coloured eggs. |

Do you need an expert in sugar or chocolate panning?